Today polyethylene pipe (PE) is used in 90% of all gas line construction and is gaining acceptance in the water industry. An Oklahoma contractor with experience in both industries is pushing PE pipe installation to new limits with the help of a piece of equipment that lays coiled pipe.

Utility Management and Construction Company (UMCCo) located in Ochelata, Oklahoma has been installing gas lines for over fifteen years and is now also gaining a reputation in Northeastern Oklahoma as the experts in development and management of rural water systems.

It just makes sense to use it for water

UMCCo recently purchased a McElroy LineTamer and is now equipped to install coiled PE pipe. The biggest advantage of installing coiled pipe is the time saved. The LineTamer removes the coil set of the pipe by forcing it through a system of hydraulically powered rollers. It also re-rounds coiled pipe to meet or exceed ASTM D 2513 ‘ovality’ requirements.

A one mile 6″ PE potable water job in Washington County for Rural Water District #2 was the proving ground for their new machine. The cross-country mainline is part of a four mile upgrade from 2″ to 6″ that will enable the water district to serve approximately 400 customers.

“We have been working with polyethylene for quite a long time in gas applications,” said David Anderson, Vice President of UMCCo. “It just makes sense to use it for water. We know that after polyethylene goes in the ground, we never have to come back because it doesn’t leak.”

UMCCo’s know-how lies in total management of rural water districts from design through installation, repair, meter reading and billing. Most of the water districts UMCCo operates enjoy rates below the state average many are debt free and all are able to make substantial capital improvements each year.

Terry Silkey, Training & Development Manager for McElroy Manufacturing was on the job location to demonstrate and train the employees of UMCCo in the operation of the LineTamer.

“The LineTamer is easy to use,” said Silkey. “The machine is so simplistic a person with a minimal amount of training can quickly become an efficient operator.”

The crew set up a staging area in a central location. The coils of pipe were carried one at a time to the LineTamer and loaded in the containment cage. Silkey demonstrated the operation on the first 500 ft coil of 6″ PE. The crew ran the LineTamer on the second coil with assistance from Silkey and then straightened three additional coils unassisted. On the first day using the LineTamer, UMCCo straightened out a total of 2,500 ft of pipe in about five hours. UMCCo had averaged about 800 ft per day on previous projects using straight lengths of pipe.

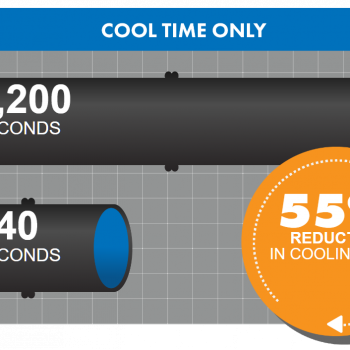

The lengths of pipe were then dragged end-to-end along the right-of-way and fused together with a McElroy Pit Bull. Each of the four fusion joints took about 15 minutes to perform. If forty-foot lengths of pipe were used, there would have been over 60 fusion joints.

“My guys where a little skeptical about the LineTamer at first but after about the third roll everyone was sold,” said Anderson. “I think with a little practice 2 people could easily uncoil over a mile of 6″ pipe a day. We estimate the LineTamer should save about four days labor for every mile of pipe we lay. What used to take a week now takes 1 day.”