We would like to congratulate Teel Plastics and Evonik Industries on the PA 12 pipe project in Henderson, Ky., which came about following the passage of the new Pipeline and Hazardous Materials Safety Administration (PHMSA) Mega Rule. The capabilities of this special pipe material provide an innovative alternative for high-pressure applications and we think we’ll being seeing a lot of jobs like this across the country in the future.

McElroy was honored to play a role in the project before it kicked off last summer by leading an informal training for Henderson’s fusion operators to reaffirm that that the process for fusing PA 12 pipe is indeed nearly identical to the process for fusing polyethylene pipe.

We love it when great pipe teams up with great equipment and fusion operators and are pleased to share Teel’s report on this trailblazing installation.

HENDERSON, Ky. — On Aug. 14-16, 2019, the City of Henderson, Ky., installed hundreds of feet of Polyamide 12 (PA 12) gas pipe extruded by Teel Plastics in Baraboo, Wis., during the first phase of a multi-stage project in the city. Henderson’s project marks the first PA 12 installation under the Pipeline and Hazardous Materials Safety Administration (PHMSA) Mega Rule (updating 49 C.F.R. Part 192) that went into effect in January, 2019.

PA 12 is an innovative material suited for high-pressure gas applications and has been used internationally for years. In the US, however, PA 12 had previously been installed only via special regulatory waivers. The new Mega Rule approved the use of plastic pipe for a greater range of high-pressure applications in the US, eliminating the waiver process for PA 12 and making it available for wider use.

Owen Reeves, PE (PA), gas system director for Henderson Municipal Gas (HMG), said he and his department were primarily drawn to PA 12 for its ease of installation compared to steel given their more difficult installation environment. HMG needed to run gas pipe through an industrialized section of the city. To minimize disruption to area businesses during the process, Henderson installed the pipe underneath driveways and roadways using horizontal directional drilling (HDD), pulling the pipe through the horizontally bored holes and then fusing the sections together. More ductile and much lighter than steel, PA 12 made the HDD installation much easier.

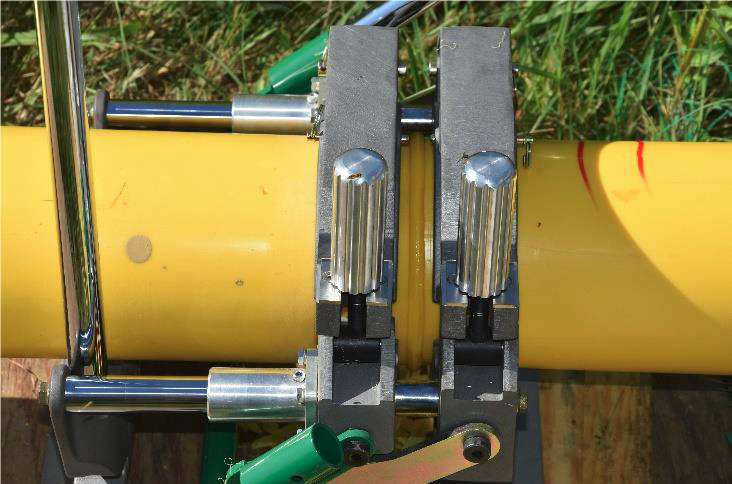

However, the primary reason Henderson chose PA 12 was the advantage it offered in joining method. The welding required to join steel pipe sections on this project would have required additional manpower and prolonged time in the field. The PA 12 butt fusion process Henderson used instead was much easier and faster, saving Henderson significant time and labor. Reeves pointed out that if Henderson had purchased steel pipe and welded the sections together, “we would have been out there for two, three weeks probably.” Instead, the installation lasted only about three days with each fusion requiring only about an hour to complete, including alignment and placement.

When initially planning the project, Owen was referred to Evonik Industries, the original developer of PA 12 material. Evonik offered Owen detailed information about the pipe and then referred him to Teel Plastics, one of the only PA 12 gas pipe suppliers in the US. Owen reached out to Teel and forged a partnership. Teel not only provided Henderson with over 2,800 feet of 200psi PA 12 pipe, but also specially designed “weak link” mechanisms to aid in the installation. These were used in each section of the pipe to help ensure that as it was pulled through the bored holes, the links would break in the event of a snag instead of stressing the pipe itself. The installation went smoothly and none of the links or pipe were damaged.

As for working with Teel on the project, “so far we’ve been very happy” said Reeves. “Teel did a great job,” he added. “They have delivered as promised and supported us.”

It remains to be seen whether more municipalities will turn to PA 12 gas pipe under the new rule, but its faster install rate, high psi rating, and imperviousness to chemical deration and wet or sour gas, are advantages that make it an appealing alternative to legacy pipe options.

Another advantage Reeves notes is that with PA 12, “you don’t have to worry about cathodic protection … you put this in the ground and you’re done with it, and so it’s great in that regard.”

Christian Herrild, Teel’s director of growth strategies said, “Teel takes pride in working on innovative products like PA 12 and working with great organizations like the City of Henderson.” He added, “We want our customers to be successful and realize the benefit of using our products by doing what it takes to support them. It should be win-win.”

For more information on PA 12 pipe, contact Christian Herrild, Director of Growth Strategies, [email protected], (608) 355-4559.