Within eye shot of the Basketball Hall of Fame in Springfield, Massachusetts, a double-barreled pipeline runs underneath the Connecticut River. The paired pipelines are one of three water main crossings that pass under New England’s longest river to service the communities of Springfield, Ludlow, Agawam, Longmeadow, East Longmeadow and several others. Like much of America’s infrastructure, the key pipelines were aging and precarious until a 2011 sliplining operation gave the pipelines new life.

Likely constructed in the 1940s or 1950s, the existing riveted steel pipelines were becoming increasingly troublesome, springing numerous leaks at the weld seams and at least one major main break.

According to an annual report from the Springfield Water and Sewer Commission, the final straw for the steel pipelines came on May 20, 2010 when a significant leak was discovered in the north 36-inch diameter pipeline. Painters working on the nearby South End Bridge noticed a plume in the river, and divers were used to discover a 2- by 4-inch hole in the pipe.

A short-term fix was identified and implemented until full-scale repair work could begin on July 5, 2011.

We were very satisfied with the pipe and fusing machine

To rejuvenate the pipeline, the Springfield Water and Sewer Commission turned to the flexibility and durability of high-density polyethylene (HDPE) pipe as the solution. Weather and logistics made the installation unique and challenging, but the reward of a leak-free system was worth the effort for the commission, contractor P. Gioioso and Sons, and pipe fusion subcontractor Vari-Tech.

The lining of the existing steel pipes was performed with a procedure called sliplining, a process where a pipeline is constructed and slid through the existing pipeline to create a new lining within the old main. However, in the case of Springfield, the typical slipline procedure was slightly altered. Often, the new lining pipeline would be fused together in a long length and pulled through the existing using a horizontal directional drilling rig or other tooling. Because of the dense urban setting along the Connecticut River, constructing the pipelines in the full 1,200 foot length was impossible.

Instead, workers constructed an entry pit approximately 30 feet deep and 60 to 70 feet long for each pipeline with sheet pile supports and steel beams. These pits served as work areas that were large enough to house a pipe fusion machine and one stick of pipe. As needed, a 50-foot stick of 30-inch IPS DR 11 piping was maneuvered into place, with a careful choreography by the crane operator. Each stick was guided through the supporting structure of the pit, placed into the fusion machine and butt fused onto the longer length of pipe.

The process to fuse the high-density polyethylene (HDPE) pipe together is known as butt fusion, and has been a popular method for creating leak-free pipelines for more than 40 years. The process starts by “facing” or shaving the pipe ends simultaneously so that the ends can be joined together with heat to create a continuous, sealed pipeline. The welding of the pipes is accomplished by using a hot plate or heater that comes in contact with the faced pipe ends. This heats the pipe to a molten state. After the heater’s removal, the pipe ends are pressed together under a controlled force to form a weld that is as strong as or stronger than the pipe itself. Third-party industry research indicated that HDPE pipe and joints like those installed can have a lifespan of more than 100 years.

Taking pipe fusion a step further, Vari-Tech engineer Bill Haines recommended a set-up called “piggybacking” that uses the cooling time of the fusion process as an advantageous time to prepare and perform a fusion joint on a second fusion machine. Only one technician is required to run two fusion machines. In the case of Springfield, walking to the other fusion machine wasn’t that simple. Fusion technician Scott DesRosiers climbed up and down a series of ladders up to 17 times a day to complete fusion joints inside the two work pits.

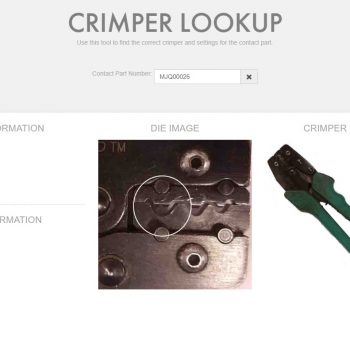

Each pit was equipped with a TracStar® 900 fusion machine provided through Vari-Tech and the Certified McElroy Rental program. The TracStar 900 fuses pipes from 12-inch IPS to 36 inches in outer diameter. The tracked chassis of the fusion machine allowed DesRosiers to make slight adjustments under the pipeline to ensure fusion operations were performed to the highest standard. The mobility of the tracked fusion unit was critical as the pipe was pulled through the existing pipeline as each new length of pipe was added to the new pipeline.

Once a fusion joint was complete, workers from P. Gioioso and Sons would radio across the river to have the pipe pulled slowly and precisely. If the pipe was just a little off, the TracStar was able to make slight adjustments and get the pipes ready for the next fusion joint.

“We were very satisfied with the pipe and fusing machine,” said Martin Lobik, project engineer for the Springfield Water and Sewer Commission. “The flexibility of the machine was critical.”

The project used Certified McElroy Rental machines that are billed as the industry’s most reliable fusion rentals. Certified McElroy Rental machines are checked after each rental by factory-trained inspectors and only use genuine McElroy parts for any repairs. All parts of the machine are checked, from top to bottom by factory-trained employees, to ensure rental fleets like Vari-Tech’s meet the customer’s highest expectations.

With the high expectations for the future HDPE pipeline, several quality assurance tools were used to ensure that proper fusion procedures were followed. DesRosiers fused every joint with the help of two McElroy Wired DataLoggers®. The DataLogger consists of a rugged hand-held computer that serves as a recording device that is attached to a data collection device that records the heater temperature and fusion pressure profile over time. All data can be transferred to a desktop computer for archiving.

Haines and DesRosiers also used the In Field® Tensile Tester, a new quality assurance tool that provides a quick and easy way to qualitatively test fusion joints in the field. Workers create a dual-reduced-section coupon that is then put into a testing unit. The test offers a quick destructive test that offers a comparison of the integrity of the fusion joint versus that of the parent pipe. The destructive test works on pipes up to 5-inches in wall thickness.

While fusion operations went smoothly, Mother Nature became the project’s biggest challenge. Hurricane Irene struck New England in late August, flooding the two entry pits and stopping work for some time. The excess water was pumped out and work restarted, unaffected by nature until an October Nor’easter dumped record amounts of snow on Connecticut. The resulting thaw again flooded the pits, requiring all equipment to be removed until the pits were clear.

“The biggest challenge was the drastic changes in the Connecticut River’s water elevation,” said Lobik. “There were periods of inactivity due to the (water) topping of our sheet pipe supporting system.”

Despite the road blocks thrown their way by Mother Nature, the job was completed in early 2012.