The first city in Kansas, Leavenworth, has undertaken a project to improve the community’s water distribution system. Starting in 2004, the Leavenworth Water Department embarked on a program to install High-Density Polyethylene Pipe (HDPE) in the downtown area. The new pipe ranges in size from 2-inch to 8-inch. The pipeline is replacing some of the old PVC and even older ductile iron pipe sections that have been in the ground for more than 100 years. Being the “first city in Kansas”, Leavenworth also has some of the oldest water pipe in service in Kansas. The city water distribution system dates back to the 1870s when water lines were made of wood. The water department has recovered some of the old wooden waterlines when repairing leaks or installing new lines in some of the older sections of the city.

A private company, the Leavenworth City and Fort Leavenworth Water Company, constructed the original waterworks system in 1881-1882. It consisted of the original (north) water treatment plant, 14 miles of transmission and distribution water mains, and the 5 million gallon Pilot Knob Reservoir. The water treatment plant consisted primarily of reciprocating pumps and the existing north reservoir, a 9 million-gallon settling basin. Leavenworth purchased the system in 1921. In September 1937, the citizens of Leavenworth voted to establish a waterworks board and a separate water department that continue today. The intent of the citizens was to ensure that the water department would be operated in a business manner. Also, all water sales revenues were to be used strictly for operating and improving the water system since the water department receives no tax revenues.

Our crews also favor the new pipe over ductile iron

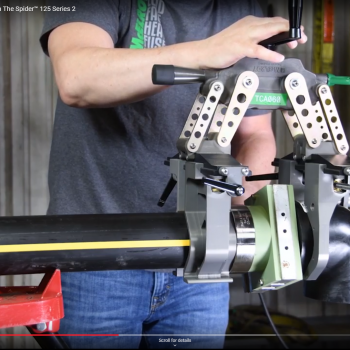

“The utility is likely to continue using the HDPE pipe in the future. We are installing the new HDPE pipe because we believe the new pipe costs less at this time and will continue to in the coming years” Leavenworth Water Department Manager Don Murphy explains. “Our crews also favor the new pipe over ductile iron because of the ease of installing the pipe and the fact that even with the larger size pipe, there are no gaskets to worry about leaking. The larger size pipe is fused together at the joints. This fusion of pipe eliminates the need for a gasket and the possible leak point in the future.”

The pipeline replacement project began in 2004 with the installation of 2-inch HDPE in a residential area. Replacement has now moved into the downtown area. The Leavenworth Water Department is also reducing costs by boring as much of the line installation as possible as opposed to excavating the city streets and sidewalks. Using the HDPE pipe in this way reduces costs as the pipe is available in large rolls in sizes 4-inch and smaller. It is very easy to pull the pipe through from end to end. The pipe is flexible and lighter than the ductile iron pipe and has great flexibility. As of June 1, the Leavenworth Water Department has installed more than 40,000 feet of HDPE pipe within its water distribution system.

HDPE has become increasingly popular in recent years for use in water and wastewater applications. It has been in use by natural gas systems for longer periods. The gas industry was among the first uses of HDPE to replace iron pipe because of its lack of corrosion and ease of installation. At Leavenworth, new waterlines and new gas lines are being installed in the same trench in the downtown areas. The installation of the two HDPE pipes in the same trench has shown that it can be completed more quickly, efficiently and cost-effectively than other types of pipe. There is a large savings in time and money, and it is less disruptive to the downtown community.

High-Density Polyethylene Pipe has been available for about 40 years. The pipe is a product originating from crude oil. From the crude oil, Naphtha is extracted and then ethylene gas is extracted from the naphtha. Through a process called polymerization, the ethylene gas is put through a catalytic reaction that causes the molecules to form long chains. HDPE is comprised of many very long chains with very little branching. The chains are packed tightly together, making for a very tough and inert plastic.

Leavenworth’s current project is the start of what is hoped will be an ongoing replacement practice of selecting areas of the town to upgrade service to the community without a lot of disruption, and at the same time, to save time and money in doing so. Reducing water loss was also a factor in implementing the replacement project. When looking at the total picture, the Leavenworth Water Department knows that not all of its infrastructure will need to be replaced at this time. However, by addressing some improvements every year, the city’s water department can make significant progress and will eventually complete the project within a reasonable amount of time. Accomplishing this project with the lowest possible cost and minimizing the inconvenience to the citizens makes the projects undertaken by the Leavenworth Water Department financially and politically acceptable to the ratepayers.

The Leavenworth Water Department currently has 34 employees who work hard to operate the water department efficiently and to meet the board’s goals of quality, abundant drinking water, friendly customer service, and economical water rates. The service area has a population of approximately 50,000 people and includes the cities of Leavenworth and Lansing (Lan-Del Water District) and six rural water districts. Water sales have averaged about 5 million gallons per day for the past 15 years. About 22% of the total water production is sold wholesale to Lan-Del Water District and the six rural water districts.