For in-ditch and close-quarter fusion, the DynaMc® is the perfect combination of performance and compact design.

The DynaMc consists of a carriage, facer, facer stand, heater, and insulated heater stand, all of which can be configured in different arrangements to allow flexibility in confined working environment.

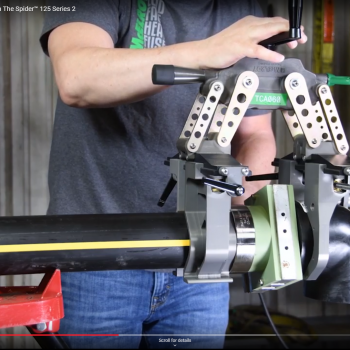

Available in 2- and 4-jaw units, the DynaMc carriage easily detaches from its cradles to further reduce the footprint of the machine. On the 4-jaw unit, the full-length guide rod and unique movable third jaw allows operators to work in close proximity to ells and trees, without the removal of the outer jaw. Three pipe size ranges are available, ranging from as small as two inches (63 mm) up to 12 inches (340 mm).

The DynaMc is available in hand pump, electric pump, and automatic models.

The DynaMc HP butt fuses pipe with hand-powered pumps, while the DynaMc EP is powered by a common hydraulic power unit.

The DynaMc Auto offers a powerful mix of features and operates within gas industry specification PL2-3 and water industry specification 4-32-08, as well as other specifications.

In addition to its flexibility in the field, the DynaMc is DataLogger® compatible, giving operators the ability to record and document key parameters of the fusion process.

Learn more about the DynaMc on its Product Page.