In 1997, McElroy revolutionized the pipe fusion industry when it introduced the TracStar® 500. And over those last 26 years, the TracStar has cemented itself as a jobsite staple.

But, as has been the case since McElroy’s inception, resting on our laurels wasn’t an option. Team McElroy knew there were ways to make the TracStar even better. Our engineers spent hours examining the company’s legacy equipment, eventually realizing that integrating the latest technology into the machine would help operators and contractors boost their jobsite efficiency even further.

Fast forward to 2020, when the TracStar® iSeries was born.

The TracStar 630i, 900i, and 1200i cover HDPE sizes from 8” IPS to 48” OD (225mm – 1200mm) and are capable of providing more than 3,000 psi for more powerful ground drive, pipe lifts, and other functions that require higher levels of pressure. The machines are self-propelled, with all of their necessary electrical equipment self-contained and on board.

These new machines offer McElroy’s new FusionGuide™ control: integrated, software-controlled options. Using the DataLogger®, McElroy’s ruggedized tablet, fusion operators could choose from three levels of control: Level 1 (Manual), Level 2 (Enhanced Guided Workflow), and Level 3 (Fully Automatic).

Full automation doesn’t only benefit seasoned operators. The FusionGuide control system has been used to bolster training for new fusion operators, cutting down on potential errors. As of March 2020, Level 3 automation makes up more than half of the fusions logged in the Vault™, McElroy’s cloud-based fusion data storage system. For the TracStar iSeries line alone, more than 19,000 fusion records have been stored in the Vault.

Owners and operators alike have embraced this new technology. The TracStar iSeries has sold more units in three years than six years’ worth of predecessor machine sales.

To date, the line has become 4.5 times more popular than previous versions of the TracStar® Series II and the TracStar® 1200.

While the global Covid-19 pandemic certainly made the TracStar iSeries’ release more complicated, its rollout matched a rising tide in the pipe fusion market. As the global economy rebounded, so did the need for our partners to replace their aging fleets. At the same time, technological advances in HDPE pipe have made for even better control and quality. As a result, the last few years have seen an increase in the demand for large-diameter (30″ or greater) HDPE, further boosting the need for more TracStar iSeries machines.

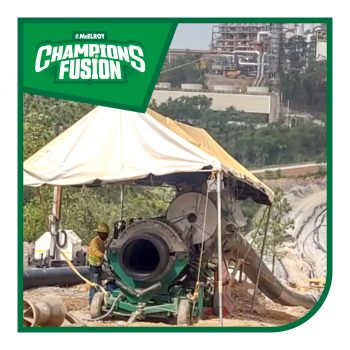

Since March 2020, the TracStar iSeries machines have gone to work in 31 U.S. states and seven countries. These machines have spent time in some of the harshest working conditions. Their performance continues to show just why McElroy is the world leader in producing rugged, long-lasting, and quality fusion equipment.

And still, McElroy is hard at work to make the TracStar iSeries line even better. Recently, McElroy introduced remote diagnostics, giving operators the ability to directly report problems to McElroy experts during the fusion process. Support staff can then seek permission from the operator to remotely connect with the TracStar iSeries machine and observe its processes. By essentially “seeing what the fusion machine sees,” tech support is then able to provide help more quickly.

Adoption of the TracStar iSeries continues to increase.

With strong demand, market growth, and customers who value machine uptime, the TracStar iSeries line will remain at the forefront of industry-leading technology and solutions that keep the job going even in the roughest of conditions.