Since 1954, McElroy has been built on a history of innovation and customer satisfaction; creating products that have become the standard of the industry, through innovative design and productivity-enhancing features. After a successful line of rolling and in-ditch fusion machines, McElroy introduced a new concept in pipe fusion twenty-five years ago.

The idea came from a job site conversation. The operator explained how much time was spent waiting for auxiliary equipment to move the fusion machine into place. His dream was to more easily and efficiently get fusion equipment in the right place. This alone would improve job site productivity whether that be in the middle of a field or a city street. Those comments did not fall on deaf ears, McElroy engineers went to work. With a fusion machine on tracks, the machine could simply move to the work. It would no longer be necessary to wait for additional equipment to move the machine into place. This concept spawned a new series of machines: the TracStar®.

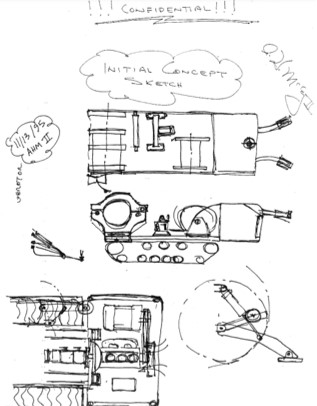

The initial TracStar napkin sketch from 1995

Cardboard mockups of the first TracStar help visualize the design

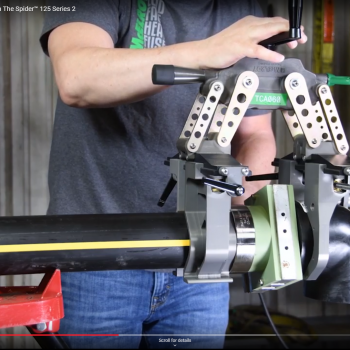

McElroy introduced the Tracstar® 500 in 1997 and it revolutionized the pipe fusion industry. The TracStar 500 was the world’s first self-propelled, self-contained, tracked fusion machine.

It became McElroy’s most recognizable machine and that series of machines has grown over the past 25 years, expanding the capability, to fuse pipe sizes from 2” to 48” in diameter.

True to McElroy’s history of innovation, the engineers were determined to improve on the existing models. McElroy engineers studied the legacy equipment, how they functioned on the jobsite, what was important on the jobsite and what operators needed to do their best. They determined systems and interactions that could be improved by utilizing the most current technology.

What resulted were numerous technology improvements and a machine layout that focuses on how the operator works with the controls. In 2020, McElroy debuted a new TracStar machine. Identified as the iSeries, these new machines offer integrated, software-controlled options from manual to fully automatic to improve operator consistency, adherence to standards, and productivity. Additionally the TracStar iSeries features new emissions-compliant engines, a CAN bus control system, along with hydraulic, mechanical, and electrical upgrades

One of the most exciting improvements is in the FusionGuide™ Control System, which powers the iSeries machines. The software offers 3 different levels of operator interaction. In Level 1 manual control, the operator manually controls the carriage position and the times during the fusion process. At Level 2, the enhanced guided workflow manages machine pressures, carriage, heater actions, shift sequence, and more. Level 3 offers a fully automatic process. No matter the level, the software guides the user through every step of the fusion process using a ruggedized tablet to ensure standards compliance and a successful fusion.

Explore the new iSeries machines to learn about the new enhancements or learn about the specific machines, TracStar 630i, TracStar 900i and TracStar 1200i, that we offer in this line.

As McElroy continues to grow, the mission statement “to make the world a better place through better infrastructure” remains at the core. New technology, new pipe types and new industries bring opportunities and McElroy is prepared to answer the challenge.