From Socket Tools, to hand held devices, to Rolling machines, there are a variety of options to choose from when it comes to meeting your Polypropylene fusion needs. Whether its butt fusion, socket fusion, miter fusion, or outlet fusion, each machine has unique qualities to cater to your jobsite’s environment.

Looking for something lightweight and compact for your polypropylene job? The Spider™ 125 is ideal for performing socket fusions overhead, vertically and in tight indoor spaces. McElroy’s Polygon™ is a three-in-one machine that can accomplish butt, miter and socket fusion. For outlet fusion, the Hornet™ is the best pick for the job.

We also have machines to meet the needs of medium and large diameter projects, including the Pit Bull® and the TracStar®. McElroy’s complete line of Rolling machines are easy to maneuver on the polypropylene jobsite and they have been providing flexibility out in the field since 1975. The wheeled chassis allows for portability, bringing convenience to jobs with longer pipelines. It also offers an easily removable 3-or-4 jaw carriage to accommodate close-quarter fusions.

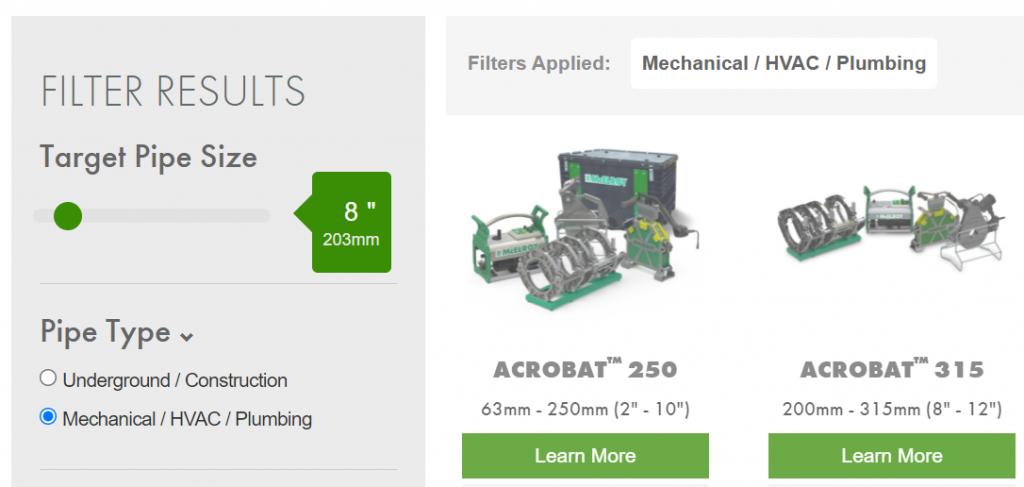

Our online Machine Finder App can help further determine which Polypropylene machine to use. Under Pipe Type, select ‘Mechanical/HVAC/Plumbing’, and it will pull up a full list of options to choose from. The machine search can be further refined by indicating the type of fusion, power type, and vehicle type that is needed for the job.