A small Oklahoma town nestled on Route 66 recently replaced one of two key pipelines that bring potable water into the city.

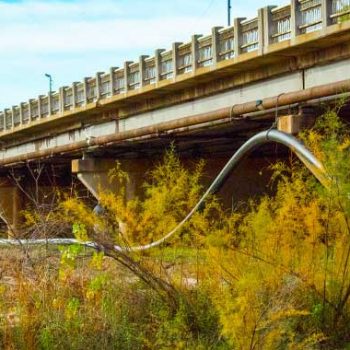

Sayre, home to approximately 4,000 residents, is served by two pipelines that bring water into the city. Those two lines come into the city by crossing the North Fork of the Red River under the protection of a bridge that carries traffic in and out of the community.

One of those lines suspended under the bridge, a 10-inch steel line constructed and welded in the 1950s, was becoming increasingly troublesome and required a solution.

As one of the main water pipelines serving the town, the reliability of the line was and is critical.

Originating from water tanks, the gravity-fed pipelines carry the water to the city. During the high-demand summer season, Sayre would be in serious trouble without one of the water lines functioning. In the lessened demand of winter, the time was perfect for a quick November and December fix of the line.

That line has had a lot of leaks, mainly at the joints where it’s been welded

“That line has had a lot of leaks, mainly at the joints where it’s been welded,” said Guy Hylton, city manager for Sayre. “We’ve put ‘band-aids’ all up and down the line. We call them band-aids, but they are stainless steel straps. They just continue to leak though, so we had to come up with a solution.”

High density polyethylene (HDPE) pipe became the material of the choice early on in the process. Polyvinyl chloride (PVC) piping wasn’t considered because the line will be exposed to the sun. Also, because the pipeline is suspended above the ground, there would have been nothing to prevent PVC slip joints from pulling apart.

“To put ductile iron in, which was one of the solutions we looked at, just the materials would have cost $50,000. With polyethylene, we were able to secure the material and pay for the labor for less than that. The durability of polyethylene is a big plus for us, and it will give and take a little bit if there’s expansion. The steel isn’t as forgiving,” said Hylton.

Polyethylene pipe had another benefit – the smooth-walled interior of the pipe creates less friction and allows more flow. This created a more effective and efficient pipeline for the city.

Hylton partnered with Milford Pipe and Supply to consult with and construct the 1,400-foot pipeline installation. Milford Pipe and Supply provides pipeline solutions for gravity flow pipelines up to 1,500 PSI injection or service lines. The majority of their expertise comes from the oil and natural gas industry, but the knowledge of creating leak-free pipelines is becoming more and more desired by rural water districts and communities that value their resources.

To construct the pipeline, a fusion technician was hired to fuse the 10-inch IPS SDR 17 JM Eagle 4710 pipeline on a McElroy TracStar® 412 fusion machine. The process to fuse the pipe together is known as butt fusion, and has been a popular method for creating leak-free pipelines for more than 40 years. The process starts by “facing” or shaving the pipe ends simultaneously so that the ends can be joined together with heat to create a continuous, sealed pipeline. The welding of the pipes is accomplished by using a hot plate or heater that comes in contact with the faced pipe ends. This heats the pipe to a molten state. After the heater’s removal, the pipe ends are pressed together under a controlled force to form a weld that is as strong as or stronger than the pipe itself. Third-party industry research indicated that HDPE pipe and joints like those installed can have a lifespan of more than 100 years.

The TracStar 412 fusion machine used by the City of Sayre to fuse the 50-foot lengths of 10-inch pipe is capable of fusing pipes sized from 4-inch IPS to 12-inch DIPS. To work with sizes under 12-inch DIPS in size, a worker places inserts within the jaws of the machine to reduce the jaws circumference.

The TracStar features rubber-mounted tracks that allow the fusion machine to travel around the job site. The all-terrain mobility allowed workers to maneuver the fusion machine through the sandy river bed of the Red River with no problem.

For Sayre, the rental capabilities of Milford Pipe and Supply helped keep the project budget friendly. Milford is a Certified McElroy Rental location, offering a premium rental option that is highly reliable. This presented a much better option than buying new machinery outright, while offering tools that arrive in a “like new” condition.

Certified McElroy Rental fusion machines are checked after each rental by factory-trained inspectors and only use genuine McElroy parts for any repairs. All parts of the machine are checked, from top to bottom, to ensure rental fleets like Milford’s meet the customer’s highest expectations. While Milford employees are trained to make sure the fusion machinery is in top shape, their fusion technicians also go through training to ensure that the proper fusion processes are followed.

One challenge that did occur during the installation was how to turn the water line off for the installation to be completed. A faulty steel valve could not be turned off after years of going unused. The solution was a 10-inch polyethylene ball valve from Central Plastics that was light enough that workers could open the existing line and bring the hand-held valve up to part of the old steel main to be attached with an MJ adapter. The same ball valve made of steel would have weighed 1,500 pounds.

The ball valve will serve as a permanent valve on the line that will allow Sayre to reliably turn the line on and off as repairs are needed down the line.

Hylton was so pleased with the speed and ease of installation that he believes there’s a future for polyethylene pipe in the community.

“We’ve definitely talked about (putting more polyethylene pipe in). We could probably use it for some sewer purposes,” said Hylton. “We might slipline some of the sewer lines we have now and we have a line going in that will run 2 miles.”

More and more communities along Route 66 and across the United States are turning to polyethylene’s reliability, longevity and leak-free structure to protect one of its most valuable resources water. This especially rings true in Sayre, which is in the midst of one of the worst droughts in Oklahoma history.

Protecting and upgrading Sayre’s infrastructure can do nothing but help the community for many years to come.