The economic lifeblood of Venezuela very well could run through the Peninsula de Paraguaná in the Estado Falcón (Falcon State) of Venezuela. The peninsula is home to the Western Hemisphere’s largest oil refinery center, the Paraguaná Refinery Center. Unfortunately, the peninsula has been plagued by an undersized and unreliable steel pipeline that provided limited water resources for the workers and residents of the Peninsula de Paraguaná. Some of those residents even relied on wells for their daily water needs and have never had water service via pipes.

Naturally, it seemed important to President Hugo Chávez to provide a stable water source to a profitable region’s residents. Between 150,000 and 600,000 residents could be served by the new 1370mm high-density polyethylene (HDPE) pipeline.

Besides the oil interests of the region, the Falcon State offers a variety of natural landscapes and is a top domestic tourist destination, offering even more financial benefits to Venezuela. International tourism could also be positively affected, as the Peninsula de Paraguaná is located just 25 kilometers south of the island of Aruba. Much like Aruba, the Caribbean provides great opportunities for the ports and potential tourist spots of the peninsula.

The sandy conditions were a huge challenge

A Key Project

The project was high-profile. Billboards with Chávez’s likeness announced the project, and what it will mean for the people. The 1370mm pipe connects the Falcon State capital of Coro (“coro” is an indigenous word that means wind) to the city of Punto Fijo, the home of the oil refinery.

Despite only having previous experience with 1220mm pipe, the Venezuelans decided to use large-diameter pipe and some of the largest fusion machines in production to fuse 28.7 Km of pipe that would stretch from Coro to Punto Fijo. One of the reasons for using HDPE was that 8.53 Km of the pipeline would cross under the Golfete de Coro, a sea inlet.

In effect, the HDPE allowed the Venezuelans to take a short cut while not risking any endangerment to the submerged pipeline. The use of HDPE is not atypical for crossing riverbanks, sea inlets and other bodies of water. The flexible nature of the pipeline allows it to flex with the curvature of the sea bottom, while remaining structurally sound. To create the leak-free pipeline, they used the technique of pipe fusion, which is common for joining lengths of HDPE pipe.

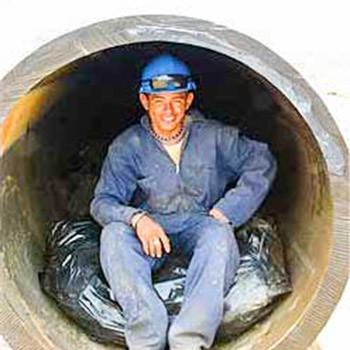

Venezuelan pipeliners woke before dawn to arrive at the critical Acueducto Bolivariano de Falcon 54-inch high-density polyethylene pipe (HDPE) water project. The workers began each day at 4 a.m. wearing elaborate apparel and protection – hard hat, safety goggles, facemasks, ear protection and full-length jumpsuits. In the afternoon, fusion operations moved to “indoor” shelters and tents to escape 55 kph or stronger winds that blew sand-loaded desert winds throughout the region.

Even though it could be classified as winter-like clothing, the extensive protective wardrobe was a must, despite temperatures hovering at or above 38 degrees Celsius. The oceanic humidity of the Caribbean bordering northern Venezuela, combined with the heat, turns human skin into a sticky canvas for the blowing sand to paint itself in layers.

“The sandy conditions were a huge challenge,” recalled Ted Amaya, director of international sales at ISCO. “We showed them how they could mitigate these conditions by using tents, much like they do in the mines in South America.”

ISCO also offered opinions on recommended equipment, eventually selling the pipe and equipment for the project.

With heat, wind, sand, and traversing water all creating manageable hindrances, the Acueducto Bolivariano de Falcon pipeline faced other challenges during construction, including the large amount of pipe required to complete the job. Two polyethylene pipe manufacturers were called upon to fulfill the huge order of 28.7 Km of 1370mm SDR 17 pipe. PolyPipe and JM Eagle produced the sticks of pipe to complete the line.

ISCO found a way to deliver the order of pipe by using three plants in the United States, and arranged for 11 charter vessels from three different ports in the Gulf of Mexico and on the West Coast for the shipments.

In planning, some deliberation took place as to how many and what kind of fusion machines to have on hand. Three large fusion machines were commissioned to the site. One of the machines, a McElroy MegaMc® 2065, proved to be the most versatile workhorse of the site. With an aggressive timeline, a second 2065 was called upon to work six days a week for three months. The second 2065 machine got the project back on schedule after other fusion machines on site required more time to complete each joint and required repairs on occasion.

Of the four fusion machines, McElroy 2065 machines fused approximately two-thirds of the 29 kilometers of pipeline.

A devout loyalty sprouted in Venezuela for McElroy machines. The workers that had opportunities to work on both types of fusion machines realized the productivity and fatigue-reducing characteristics of the MegaMc 2065. While other machines were producing an average of four joints per day, the 2065 machines averaged 10 joints per work day.

The MegaMc 2065’s design and height clearance allowed the workers to shelter the machines in tents at times to keep the windblown sand from contaminating the fusion joint. The other fusion machines on the site required a crane to lift the facer and heater plate up and then lower those pieces into the carriage to perform their functions. This eliminates the opportunity to shelter those joints from the sand, as the clearance height of the crane is much taller than most tents.

McElroy’s MegaMc machines incorporate hydraulic power for several functions, including the clamping jaw operations, pipe lifts, heater plate operations, and facer operations. This extra power eliminates hand-wrenching jaws closed and more efficient facing of the pipe, thus speeding the process.

Undoubtedly, HDPE was the right choice for the cross-desert, underwater pipeline. As Venezuela continues to export oil and import some tourism to its Caribbean coast, the Acueducto Bolivariano will continue to provide water throughout the Falcon State.