Our annual networking conference for the plastic pipe industry — INFUSION — took place last month and one of the most exciting events in the lineup of programs is always our Product Showcase. This offers our guests a hands-on experience with all of our new fusion equipment and gives them an opportunity to interact with the engineers who designed them.

Here are some of the highlights from the show:

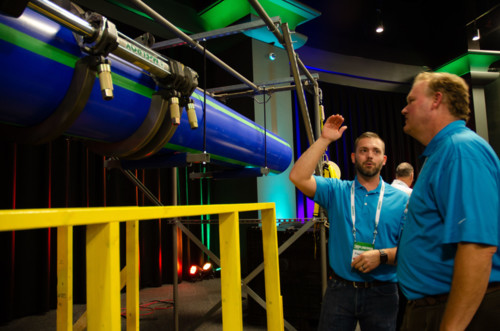

ACROBAT™ 355-630 WITH QUIKFIT® CARRIAGE

McElroy’s Acrobat machines featuring the QuikFit carriage have a revolutionary jaw design that allows operators to fuse polypropylene pipe from 355mm to 630mm (14″ to 24″). This machine was built based on feedback from end users, distributors and pipe manufacturers and the need for a fusion machine that would facilitate fusing large-diameter pipe inside buildings, mechanical rooms and other close-quarter environments.

- Modular, lightweight carriage and facer assembly around the pipe for optimal close-quarter fusion

- No tools required for assembly or conversion to 3- or 4-jaw unit

- Jaws fit 355mm/400mm, 450mm/500mm or 560mm/630mm pipe — no inserts necessary

- Core package can be used with any Acrobat 355mm-630mm package

- Facer blade orientation allows shavings to fall inside or outside of pipe

- Stackable shipping container designed to store all machine components

Learn More about Acrobat with QuikFit Carriage

355mm/400mm 450mm/500mm 560mm/630mm

POLYGON™

The Polygon allows installers the flexibility to complete butt and miter fusions from zero- to 45-degree angles and has the additional capability to perform socket fusions. This three-in-one machine’s simple design and light weight make it the ideal prefabrication tool on 63mm to 160mm polypropylene pipe jobsites.

First manual machine with DataLogger® capability

Produces miter, butt and socket fusion joints for polypropylene/polyethylene pipe

Quick clamp pivoting jaws for faster, easier setup

Adjustable, pivoting pipe supports to keep the pipe level in the jaws

Quick open/close, non-back-drivable wheel drive for smooth jaw movement

Coming soon! Jaws for polyethylene pipe up to 180mm

HORNET™

The Hornet is an industry-first, all-in-one tool for polypropylene outlet fusion for branch sizes 20mm to 63mm on to 40mm to 630mm main sizes. It brings an innovative alternative to manual outlet fusion methods that is more productive and reliable. Building on its quick popularity, the Hornet will soon be available for branch sizes up to 160mm.

Quick-change drill and fitting adapter for efficient fusions

Rack and pinion drive for smooth operation

Self-centering base design ensures fusion operations align on center of pipe

Integrated ratchet strap allows operation across wide range of pipe sizes

Lightweight and compact

Coming soon! Two sizes for outlet fusion

TALON™ 2000

Building on the Talon’s success, we now offer additional size capabilities. Inserts, quarter jaws and a smaller 1,200mm heater are now available for fusing 1,000mm to 1,200mm (36″ to 52″) pipe. With the unique, self-loading features of the Talon, which eliminates lifting pipe overhead, this provides a safe and efficient method for fusing pipe in this size range.

Self-loads pipe from the ground

Self-contained, self-propelled

Track-mounted for maneuverability

Terrain following and pitch control to better align with pipe

Top-loading heater and facer, no cranes necessary

Electric-powered indexer accurately positions heater and facer

New! Additional jaw size capabilities

TRACSTAR® 412 SERIES 2 AUTOMATED WITH RETRACTABLE HEATER

The TracStar® 412 Series 2 Automated is available with a new self-retracting heater. Designed to meet regulations within the UK, this self-retracting heater eliminates human interaction with the heater.

- Fuses 4″ IPS to 12″ DIPS (110mm-340mm) pipe

- Self-contained, self-propelled, all-terrain

- The Coach ® Pendant 2 controls all functions

- Powered by a diesel engine

- Redesigned cowlings for better airflow and ease of maintenance

- On-board generator for powering the heater

- New! Now available with self-retracting heater

DATALOGGER® 6 AND VAULT™

Building upon the success of the DataLogger ® since its introduction in 1996 and taking into consideration the evolving environment of accountability within our infrastructure markets, we made a significant investment in the next evolution of the platform. The DataLogger 6 is a comprehensive redesign of our digital fusion logging and management platform that incorporates a state-of-the-art rugged tablet input device powered by a modern, fresh software and user interface.

Android powered, 7″ HD screen

IP67 water and dust-resistant tablet

Meets ASTM F3124 standard for data recording of heat fusion joints

Real-time visual graph generation

Captures GPS location

2D barcode scanner inputs pipe and fitting information

The McElroy Vault complements the DataLogger 6 with a secure platform to collect, store, analyze, and share comprehensive fusion jobsite information. The Vault allows a deeper review of fusion joints with easy-to-interpret FusionGuide™ graphs that can be viewed from anywhere there’s a connection to the internet.

A number of enhancements have been made to the Vault which include:

Editing tools to update job records

Notes section added to joint reports

Tags for review, accepted or rejected joints

Jobs can be sorted by most recent activity

Ability to download or print PDF reports

LEARN MORE ABOUT DATALOGGER 6 LEARN MORE ABOUT THE VAULT